Certified Company

FACILITIES & INFRASTRUCTURE

Hirva Die Cast India LLp., have a Pressure & Gravity Die Casting section for Die Casting of Components, Tool Room for Manufacturing of Pressure & Gravity Dies, JIG & Fixtures. Fattling, Drilling & Tapping, Blasting and CNC Section for Finishing & to make ready for dispatch of Components.

IE has 13 CNC turning centers, which include double spindles that are solely used for machining castings. Each machine is equipped with NABL calibrated air gauges to check the machined components. In addition, we use a bore gauge, height gauge, flat plate, basic vernier, and scales, as well as other gauges to thoroughly inspect the machined parts. Our strict checking process and infrastructure upgrades enable us to maintain a 1.5 CPK level. We have also implemented a corrective system to ensure consistent quality throughout our production process, delivering high-quality products to our customers.

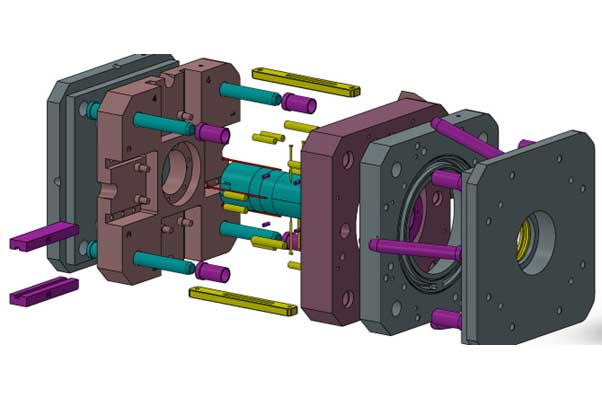

Our company boasts two comprehensive tool CAD and CAM stations that are fully equipped with multiple VMCs, EDMs, and other conventional mould manufacturing machines. Our experienced team of tool room machinists and die designers can produce 45-50 tools per year. We have ambitious expansion plans that involve adding more VMC and CNC machines to increase our mould manufacturing capacity to 65-70 tools over the next two years. Additionally, we have partnered with a reputable simulation consultancy firm that provides us with mould flow analysis for large and complex moulds.

Overall, die designing is a critical step in the die casting process and Ishaan Engineering is committed to produce the superior quality of tools for consistent quality.

At our company, we have separate electric melting cum holding furnaces that offer us the flexibility to melt different grades of aluminum alloys simultaneously, including ADC-12, LM-6, LM-24, and ALSI-132. We strictly adhere to the use of RoHS grade material and food-grade alloys. Since aluminum has the highest recyclability ratio among metals, it is an ideal material for manufacturing metal parts. Thereby our commitment to sustainability and the cradle-to-cradle concept is supported by this approach.

At our works, we have a range of 3 shot blasting machines that come in different types and sizes. These machines include tumble blast and hanger type blasting machines, providing us with the flexibility to conduct shot blasting on various parts without causing damage. Shot blasting is a surface finishing process that involves the use of abrasive media, such as steel shot, which is propelled onto a surface with high-pressure air. This abrasive media eliminates surface contaminants like rust, scale, and paint, and enhances surface adhesion for coatings and paint by providing a rough surface texture.

We have a powder coating facility on-site which enables us to provide ready-to-assemble parts. Our plant is fully equipped with a four-tank process for pre-cleaning and surface activation to enhance adhesion of the powder onto the component’s surface. Following post-cleaning, we have two conveyorised booths for efficient powder coating, after which the parts are loaded for baking. Our skilled workers are capable of coating intricate and complex parts for various industries, including luxury LED lighting heatsinks, compact CCTV parts, fan covers with aesthetic appeal, and other engineering components.

We have developed a primer coating facility at our premises to cater to the needs of our electric motor OEM customers. This enables them to directly assemble the motors on the production line. The purpose of the primer coating is to extend the life of the part by preventing rusting and oxidation in an open environment. It also improves the overall appearance of the part and provides a uniform finish. We are currently in the initial stages of mass-producing primer-coated parts, and plan to add an entire line dedicated to primer coating to meet the increasing demand for electric motor requirements.